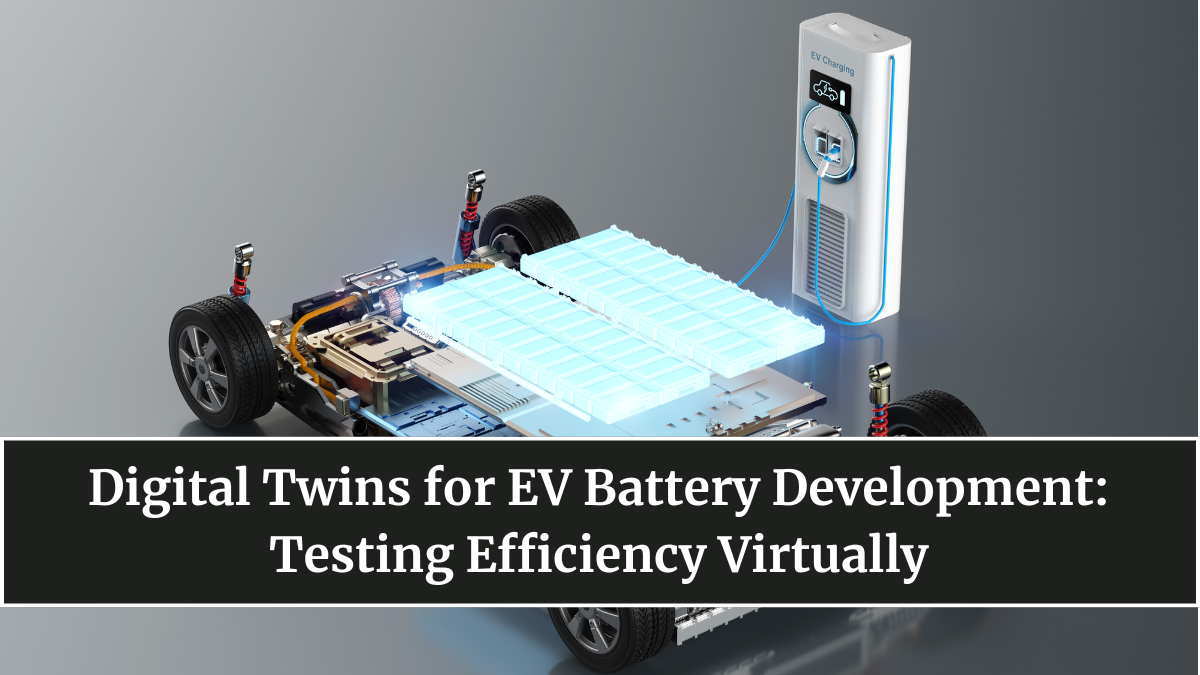

In 2025, digital twin technology has become a breakthrough tool for the electric vehicle industry, especially in battery research and development. By creating virtual replicas of real batteries, automakers can simulate every aspect of performance — from cell chemistry to thermal management — long before physical prototypes are built. These digital twins for EV batteries enable faster innovation, safer designs, and a more sustainable production process.

What Are Digital Twins in Battery Development?

A digital twin is a virtual model that mirrors a real-world system using real-time data and predictive analytics. For EV batteries, it represents every layer of a cell or pack — including materials, structure, temperature behavior, and energy flow.

By syncing with live sensor data, digital twins allow engineers to test, predict, and optimize battery behavior in simulated environments. This eliminates the need for repeated physical trials, drastically cutting down time, cost, and waste.

Manufacturers like Tesla, CATL, and LG Energy Solution are at the forefront of adopting digital twin frameworks to enhance battery reliability and lifecycle analysis.

How Digital Twins Improve Battery Design

Traditional battery development relies heavily on physical testing, which is time-consuming and expensive. Digital twins, however, combine AI, IoT sensors, and physics-based models to simulate real-world conditions virtually.

Key improvements include:

-

Thermal Management: Predicts overheating and optimizes cooling systems before production.

-

Material Efficiency: Tests different electrode compositions digitally to identify the best balance between cost and performance.

-

Lifecycle Simulation: Models degradation over thousands of charge cycles to forecast long-term performance.

-

Safety Validation: Identifies potential short-circuits or failures under extreme conditions without risking real assets.

These capabilities ensure better-performing, longer-lasting, and safer batteries, accelerating EV adoption globally.

Integration of AI and Cloud Computing

AI and cloud technologies are central to digital twin ecosystems. With continuous data collection from real EVs on the road, AI algorithms refine virtual models in real time. This feedback loop enhances simulation accuracy and enables predictive maintenance.

Cloud-based platforms like Siemens Xcelerator, NVIDIA Omniverse, and Dassault Systèmes 3DEXPERIENCE provide automakers with scalable digital twin infrastructure, allowing global collaboration on design and testing.

This synergy between AI and high-performance computing is revolutionizing how engineers develop, validate, and deploy next-gen EV batteries.

Benefits for Automakers and Consumers

The impact of digital twins extends beyond R&D labs. Automakers benefit from:

-

Shorter product cycles and faster time-to-market.

-

Lower prototyping and testing costs.

-

Improved sustainability through reduced material waste.

-

Enhanced quality control via real-time data monitoring.

For consumers, it means EVs with longer range, greater reliability, and improved safety. As battery performance becomes more predictable, warranty claims and degradation issues decline significantly.

Sustainability and Circular Economy

Digital twins also contribute to battery recycling and second-life management. By tracking every cell’s digital profile from manufacturing to retirement, companies can identify optimal reuse strategies — such as repurposing old batteries for energy storage systems (ESS).

This transparency supports a circular battery economy, ensuring valuable materials like lithium and nickel are reused efficiently rather than discarded.

The Future of Digital Twin Technology in EVs

By 2025, nearly every major EV manufacturer employs digital twins in some phase of design or operations. The next phase will involve real-time twin integration across entire production lines, allowing AI to autonomously adjust manufacturing parameters for maximum yield.

Looking ahead, battery digital twins will integrate with vehicle digital twins, enabling full-system simulation — from motor control to energy flow. This unified virtual ecosystem will drive smarter, greener, and safer electric mobility for decades to come.

FAQs

What is a digital twin in EV batteries?

It’s a virtual replica of a real EV battery that uses data and simulations to predict performance, optimize design, and reduce testing time.

How do digital twins benefit battery development?

They help detect faults, test materials virtually, and extend lifespan by modeling real-world conditions before production.

Which companies use digital twin technology for batteries?

Tesla, CATL, LG Energy Solution, and Siemens are among the leaders in adopting digital twin solutions for battery systems.

Can digital twins help in battery recycling?

Yes. They track battery usage and health, enabling efficient recycling and second-life applications for energy storage.

What’s the future of digital twins in EVs?

Future EVs will use integrated digital twins for entire vehicles, combining real-time AI and cloud systems to optimize performance and sustainability.